Inside Made in China: Metal Processing Discovery

Hello community, and welcome back to our fourth volume of Inside Made in China. For those of you who are new to this series, it is all about how things are “Made in China”. We’re curating series posts to tour you around online to local factories in Dongguan, where sits our new Chaihuo x.factory Dongguan. We regard it as an interface for the global maker community to the local manufacturing system, with the aim to open up the local manufacturing resources to the global maker community, lower the manufacturing barrier and help you to gain a better understanding of the local manufacturing ecosystem.

For this time we are taking all of you into another big field of manufacturing; Metal processing, where majority of the metal components inside machinery can be manufactured through here, via different techniques. At first, I would like to say a big thank you to Mrs. Yang for inviting us to tour around her factory and allowing us to have a real footage of how components are manufactured. Fumanchang Metal Products Co, Ltd. situated in the Tangxia subdistrict, Dongguan, where it’s only 40 minutes away from Shenzhen and 50 minutes from Hong Kong. For this, Fumanchang can fully facilitate the beauty of Shenzhen’s supply chain ecosystem in terms of delivering goods and ensuring high efficiency.

Capable of metal stamping, CNC component processing and sheet metal processing, Fumanchang held 48 metal stamping machines, 57 Computer numerical controlled lathe, and a total of 50 mechanical processing machines.

Punching Workshop

At the first stop of the factory, we entered the punching workshop and all the finished products are manufactured using the stamping machines. I was very impressed by the production efficiency, where one stamping machine can produce roughly 220 components per minute. What’s more, each machine can be set up to manufacture different components (i.e. different CAD drawings), meaning that each stamping machine can be a production line itself, maximizing the production capacity. And only few workers are required on the floor to load up materials into machines at the beginning of the process and ensuring the proper functioning of the workflow.

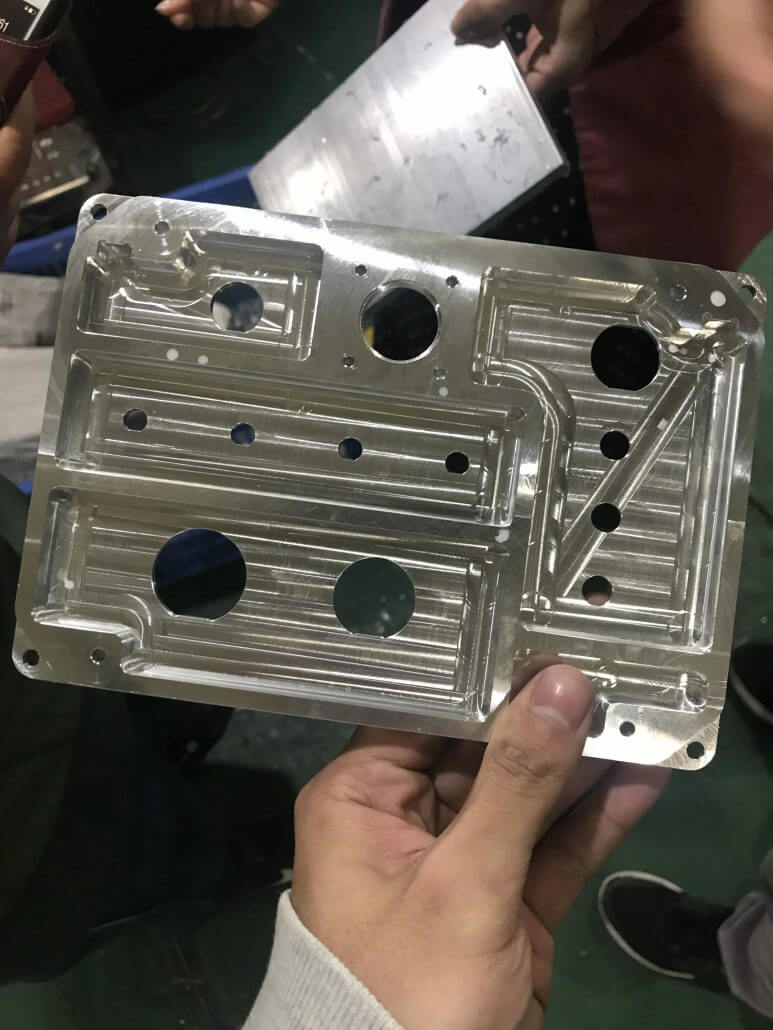

Next up, we visited the CNC workshop where it handles components that require CNC lathe, CNC milling, CNC bending or even NCT machines with compound laser processing. In this session, components are treated using CNC machines, meaning that higher accuracy and capable of manufacturing more complex structure in an automatic manner.

CNC Milling

For some components, Fumanchang can provide assembly processes in which they use an automatic screw feeding system to accelerate such process.

For small batch productions, it may not be necessary to facilitate automations due to cost-wise. Therefore, Fumanchang employs a small metal processing workshop for post-processing including process like drilling, welding and etc.

Last but not least, we entered the quality control sessions, where each of the finished component would require to pass its correlated tolerance range in order for warehousing and eventually delivering to clients. Here at Fumanchang, QC is still managed by labour force due to the high mix, different batch sizes and range of finished goods causing difficulty to set up automatic equipment.

If you have any concerns regarding these metal processing techniques, please feel free to add few comments below and stay tuned until next time!

–

This factory HI (Hardware Innovation) tour is a customised service provided by Chaihuo x.factory Dongguan and so if you have any factory visiting inquiries or you want to make use of innovation and manufacturing resources gathered by the x.factory community to transform your project from 0 to 1, Please email us at [email protected]

Everything looks very professional. Wish your company a prosperous future!

Awesome!!!