Agile Customization

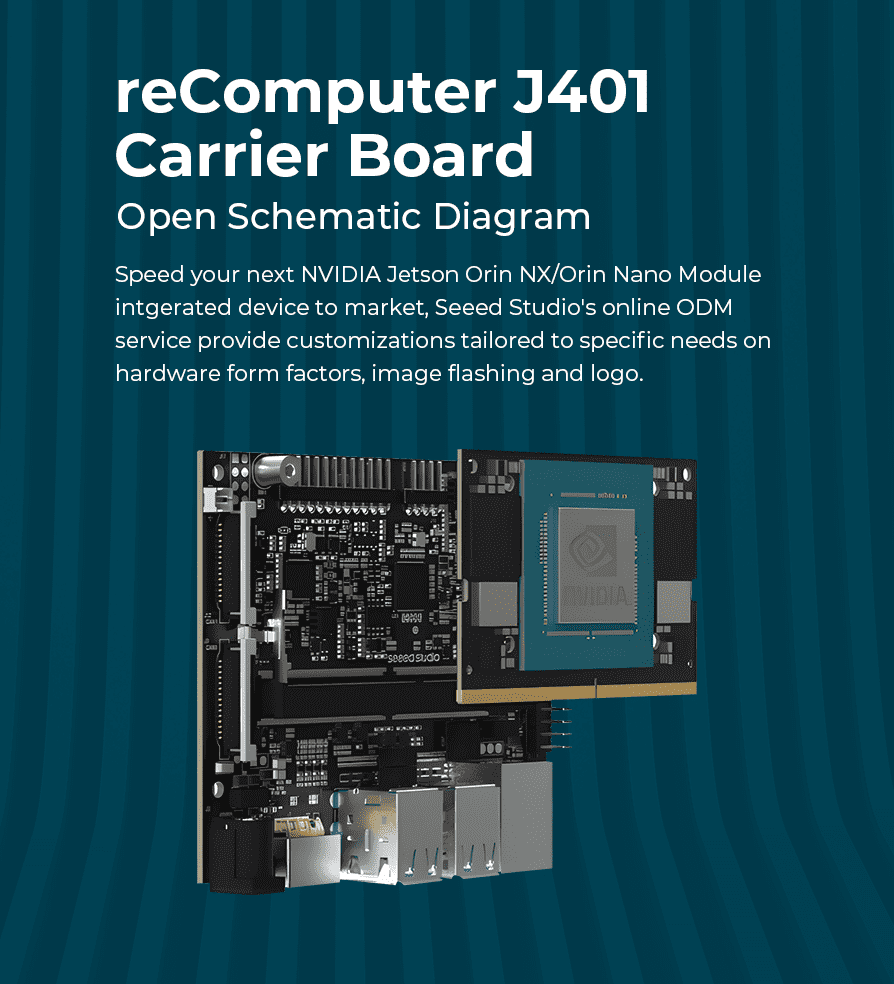

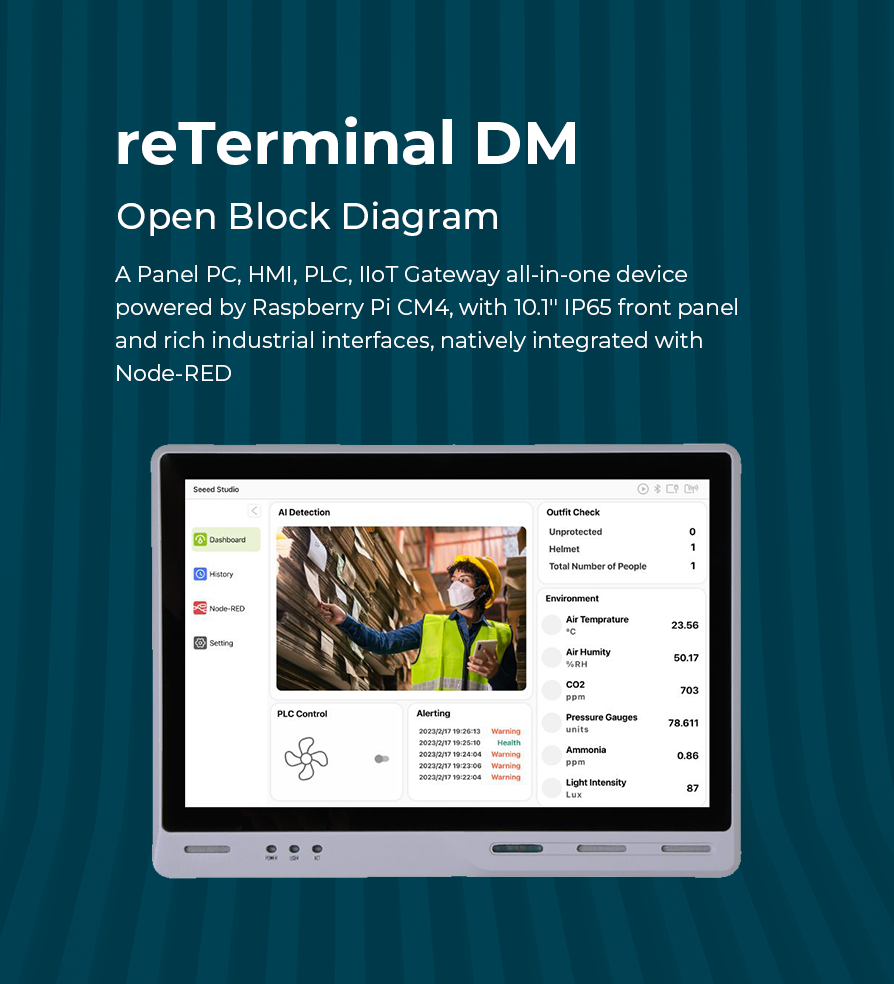

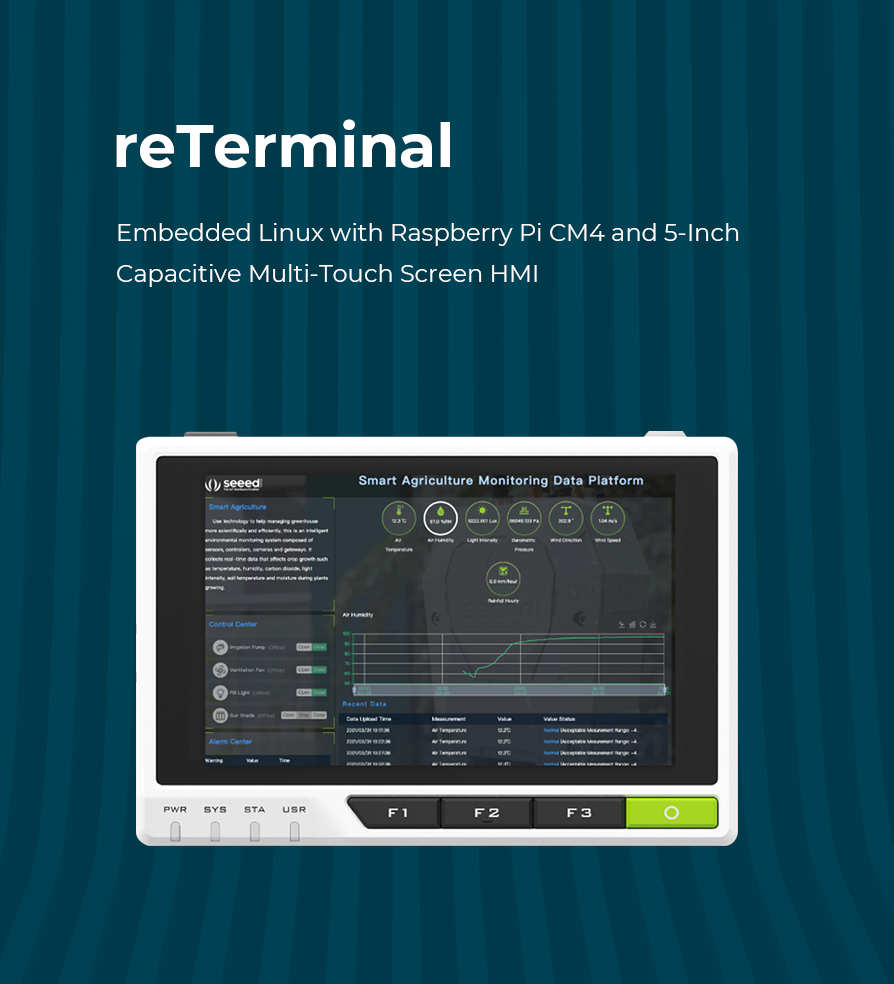

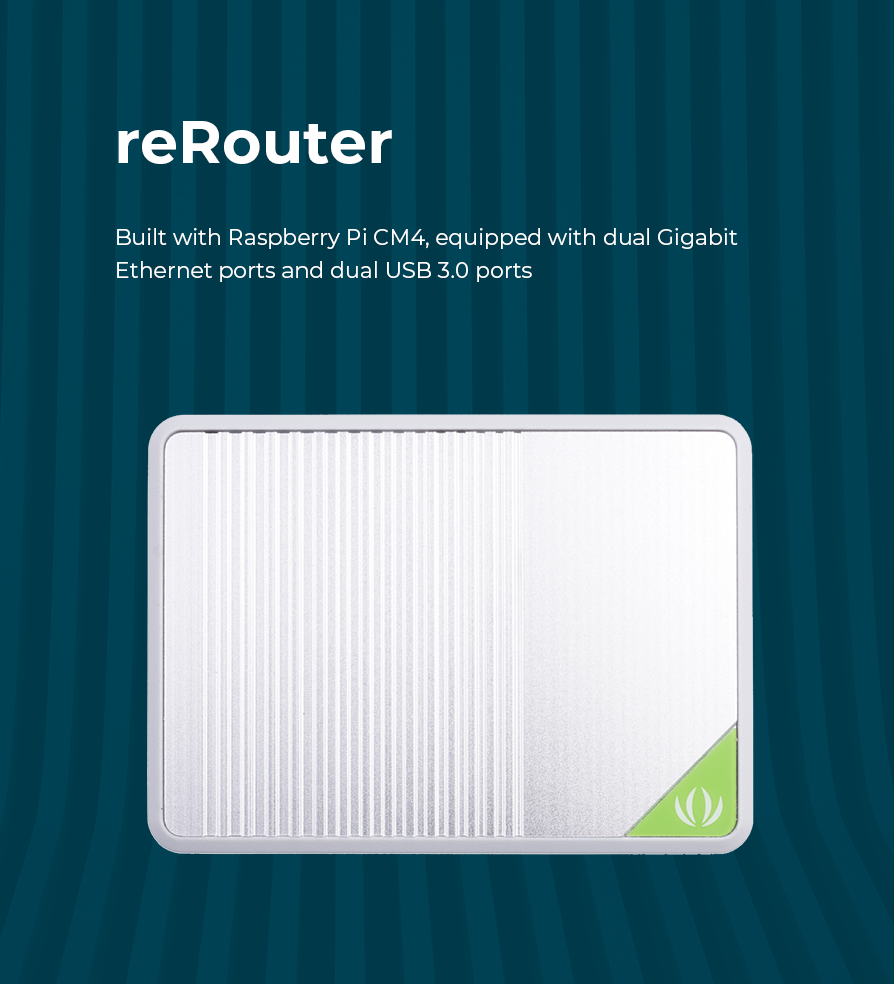

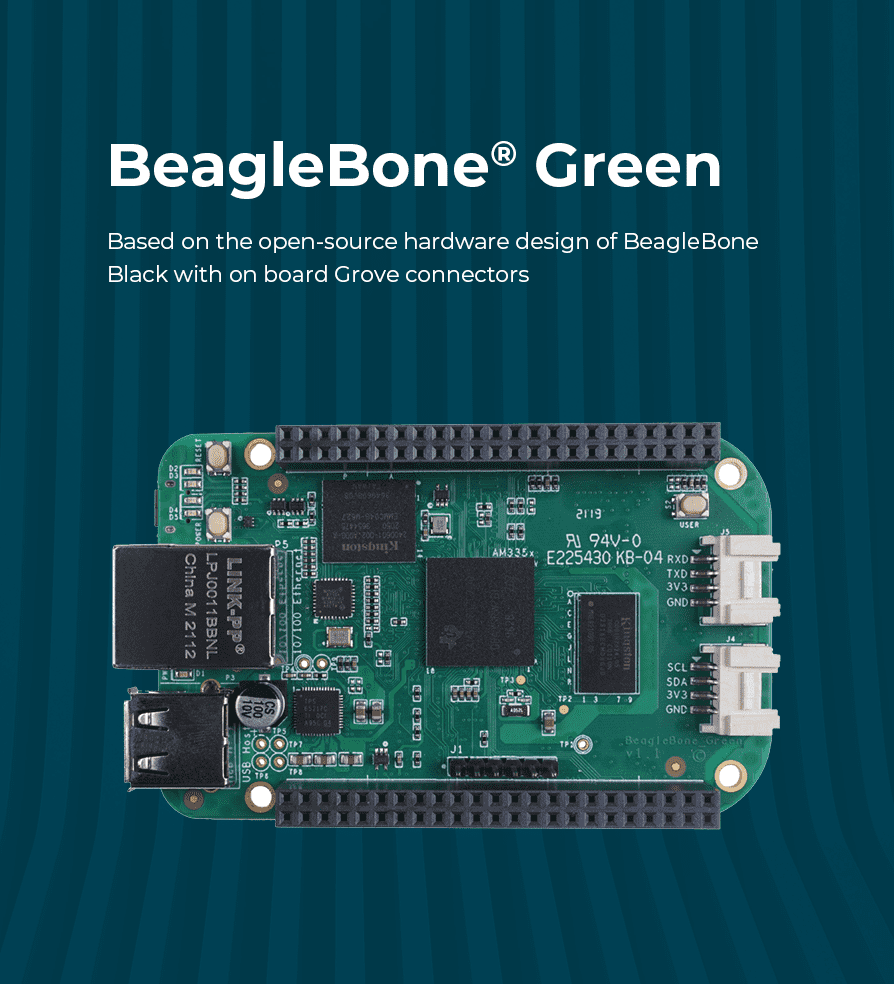

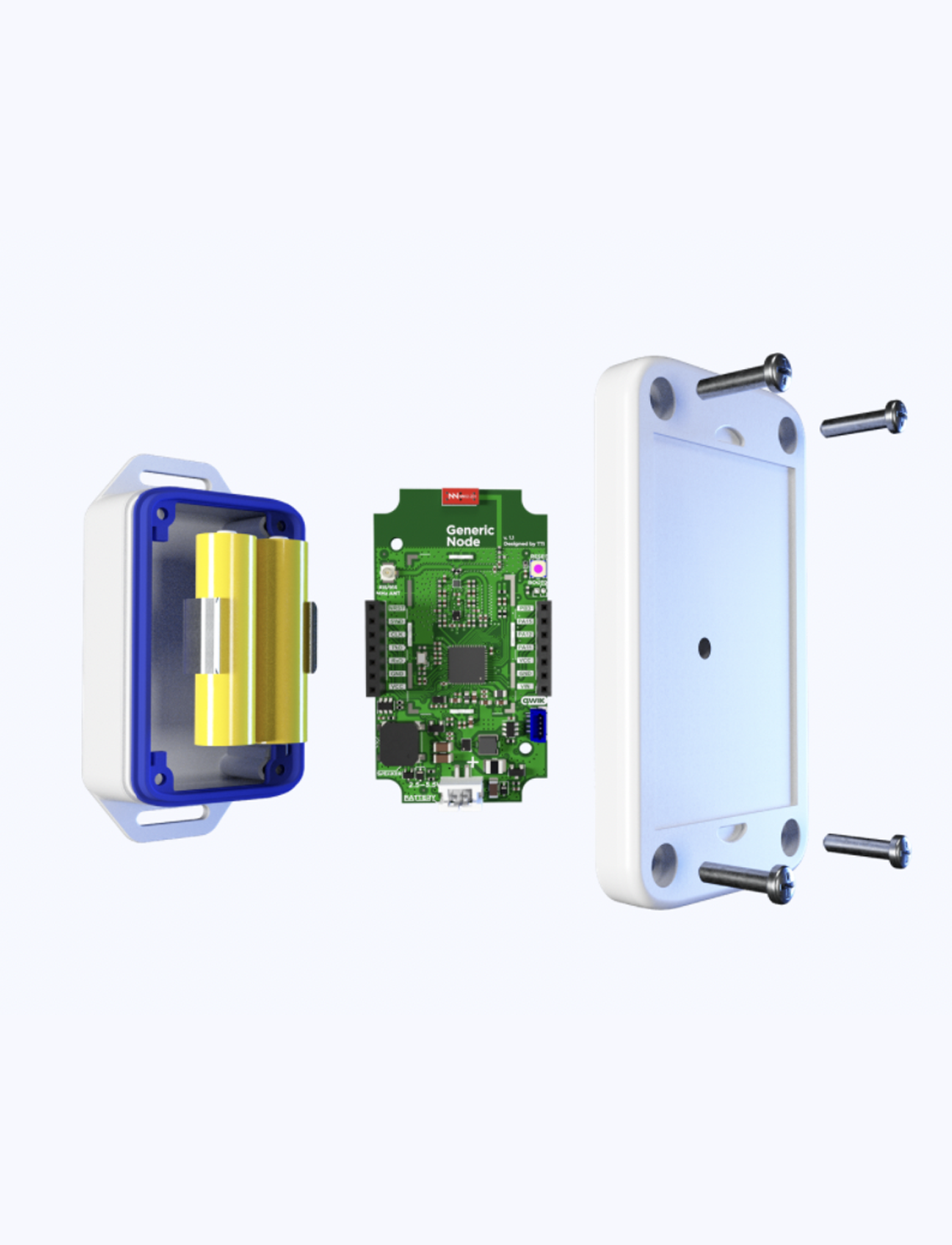

With decades of ODM & OEM experience, our engineers and product experts are proficient in delivering customization service for popular open-source hardware platforms – NVIDIA® Jetson™, Raspberry Pi®️, Beagleboard®️, and more.

With Seeed Studio’s customization and manufacturing service, we are ready to bring your product concept to the market with Seeed Studio’s industrial capabilities from design, manufacturing, testing, certification, global distribution and marketplace.