Underground Tracking Technologies Compared: LoRaWAN vs GNSS vs UWB vs Wi-Fi

Underground mines may look like indoor environments, but their long tunnels, sharp turns, heavy metal machinery, and rock walls create wirelesss conditions that behave nothing like offices or schools. These harsh conditions place unique demands on underground mining tracking technologies, where reliability matters far more than ideal indoor accuracy.

This blog breaks down how GNSS, Wi-Fi, UWB and LoRaWAN actually performs underground, and what mining solution providers need to consider when designing underground tracking technologies.

Why Tracking Matters Underground

Underground mines operate in environments where visibility is low, communication is limited and conditions change without warning. Miners are sometimes required to work alone. When something goes wrong, every second counts. Without reliable tracking, supervisors have no clear picture of where people are, who is closest to danger, or which assets are unaccounted for, a critical in underground tracking technologies.

Tracking matters because it helps mines:

- Protect workers with real-time personnel tracking and faster emergency response.

- Support lone-worker safety with last-known-location and panic alerts.

- Locate equipment quickly using underground asset tracking solution to avoid delays.

- Supports visibility and communication practices recommended by MSHA.

The Underground Problem

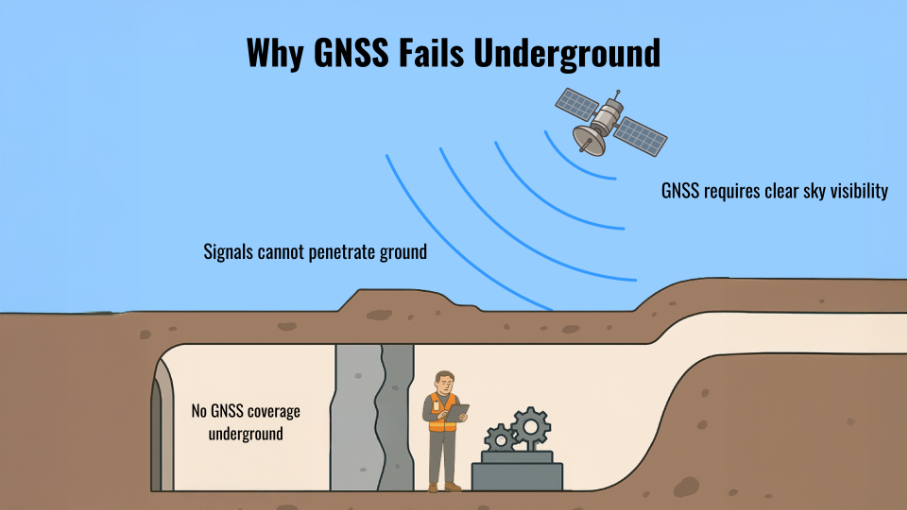

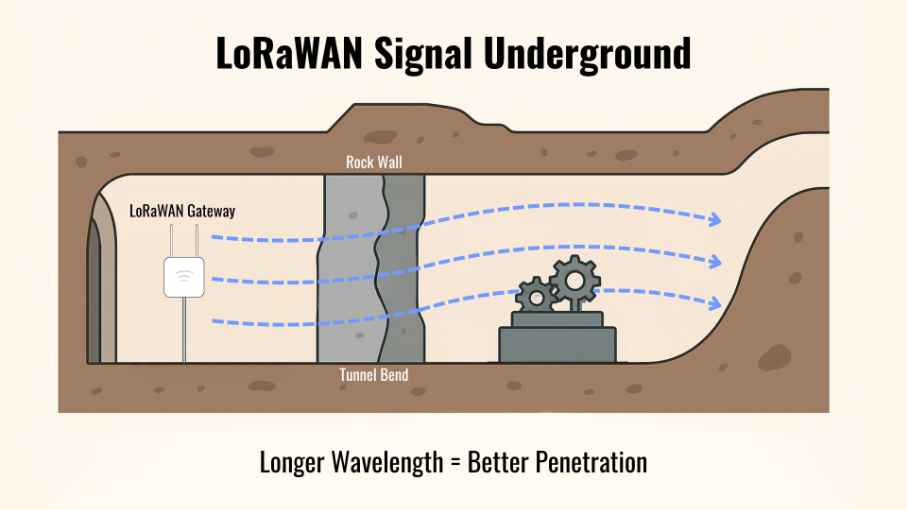

Underground mines introduce physical conditions that most wireless systems aren’t designed for. GNSS relies on satellite visibility, so it stops working the moment workers move below the surface. Signals like Wi-Fi, UWB and BLE face heavy attenuation from rock, metal structures and machinery. Long, winding tunnels also cause rapid signal decay.

Power access is limited underground as well, making it hard to maintain dense infrastructure or recharge devices frequently. These constraints mean underground tracking technologies must rely on networks that remain stable even when conventional wireless signals fail.

Technology Comparison Table (Underground Edition)

| Technology | Reliability | Infrastructure Needs | Power | Cost |

| LoRaWAN | Strong; best penetration | Low | Low | Low |

| GNSS | No Signal (requires sky visibility) | None | Low | N/A (Unusable underground) |

| Wi-Fi | Inconsistent | High | High | High |

| UWB | Limited range; affected by tunnel geometry | High | Medium | High |

Why Choose LoRaWAN

LoRaWAN is one of the strongest options for underground environments because it uses Sub-GHz frequencies with longer wavelength. These signals travel farther through rock, bends and long tunnels, and are less prone to signal loss in irregular environments. It supports safety alerts, worker presence, environmental monitoring and BLE-based zone tracking, offering wide coverage with low maintenance and efficient power use.

When to Choose UWB Instead

Choose UWB for small underground zones where precise positioning really matters.. UWB performs well in areas such as equipment bays, maintenance rooms, material loading points or automated machinery zones, where knowing the exact position of people or assets is important. Its centimeter-level accuracy helps mines verify movement, track asset placement and manage restricted areas more reliably than wide-area networks.

Why a Hybrid Approach Works Best Underground

Most underground tracking systems use a layered system instead of relying on one technology. This ensures you aren’t paying for expensive precision where it isn’t needed.

- The Backbone (LoRaWAN): Provides wide-area coverage for data backhaul and reliable alerts across kilometers of tunnels.

- The Zone Tracking (BLE):: Adds cost-effective presence detection in specific rooms, or work sites.

- The Precision Layer (UWB): Deployed where centimeter-level accuracy is needed.

This hybrid approach keeps infrastructure costs down while ensuring the right level of visibility mines need.

Deployment Cheat Sheet

| Technology | When? | Why? |

| LoRaWAN | Mine-wide coverage | Most practical setup for underground tracking and safety alert Supports mine-wide coverage when paired with BLE for zone-level visibility. |

| UWB | Small zones that require high precision | Provides centimeter-level accuracy for proximity and collision-avoidance areas. |

| GNSS | Where sky is visible | Does not work underground, but it’s perfect for open-pit fleets and surface workers. |

| WiFi | Mine already installed it | Too costly and inconsistent to deploy from scratch just for tracking |

A Practical LoRaWAN + BLE Safety Solution for Underground Mines

Seeed provides LoRaWAN and BLE hardware that supports underground worker and asset visibility, including panic alerts, presence updates and simple zone-level tracking. Paired with industrial LoRaWAN gateways and BLE beacons, it offers a low-maintenance foundation for mine-wide deployment.

No two mines are the same. For sites with specific layouts or operational requirements, the setup can be customised, from device behaviour to data integration, to fit different underground tracking needs.

Ready to deploy underground tracking? Talk to us.