2025 MFSZ · Hi Tour — Shenzhen Manufacturing Innovation Journey

The 2025 MFSZ · Hi Tour — Shenzhen Manufacturing Innovation Journey successfully concluded on November 17, gathering 70 global makers and Innovation Ambassadors from more than 20 regions including New Zealand, the United States, Germany, Mexico, Brazil, India, the UK, France, Italy, Canada, Indonesia... For many participants, this was their first time setting foot inside China’s world-renowned hardware ecosystem — an experience described unanimously as inspiring, eye-opening, and unforgettable.

This year’s Hi Tour offered a full-day deep dive into the Greater Bay Area’s unique supply-chain advantages, the evolution of Seeed Studio, and the real stories behind how ideas become mass-manufactured products.

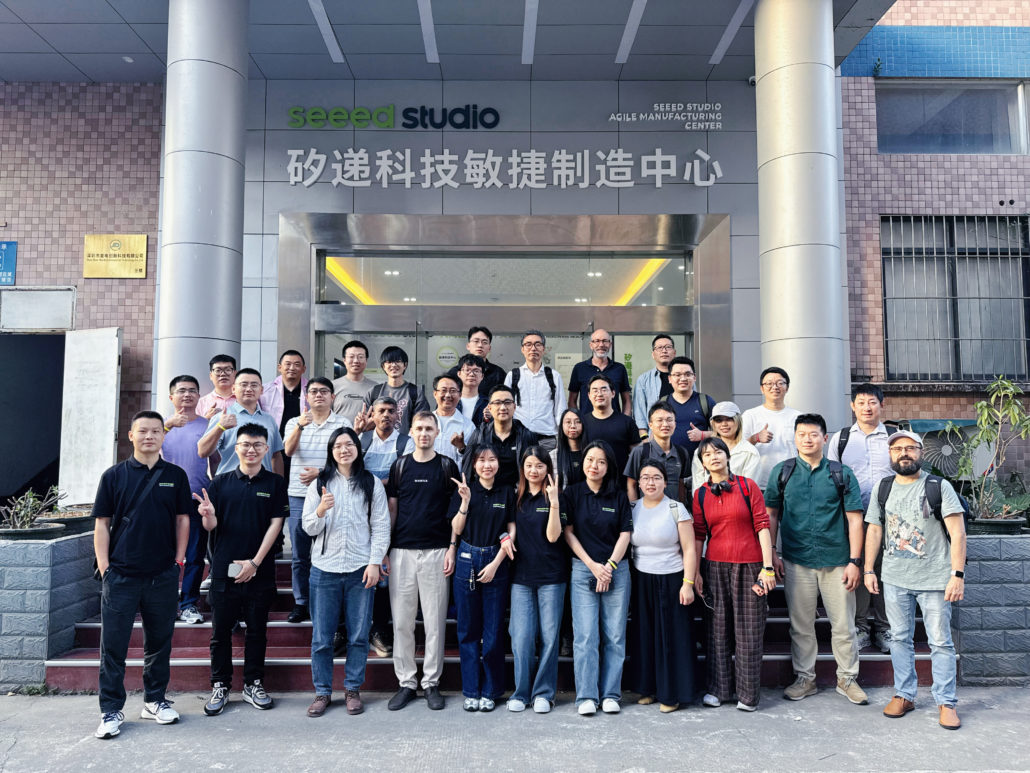

A First-Hand Look at Seeed’s Agile Manufacturing Center (AMC)

The journey began at Seeed’s Agile Manufacturing Center (AMC) — the backbone behind Seeed’s hardware business. Participants explored the complete path from prototype to small-batch production, including:

- IQC & raw material warehouse

- SMT production lines

- Finished-goods warehouse

- Wind-tunnel laboratory

- Seeed’s new robotic assembly line

Through real factory workflows, visitors learned how Seeed solves long-standing challenges faced by hardware innovators — such as manufacturing constraints, limited project management resources, QA bottlenecks, and the high cost of small-batch production.

Seeed’s AMC demonstrated how the team supports customers from 0 to 1,000 units and beyond, covering rapid prototyping, EVT/DVT engineering builds, small-batch assembly, functional testing, packaging, and mass-production transfer through trusted partners.

From Modules, to Devices, to Industry Solutions

In the AMC exhibition hall, guests followed a curated walkthrough:

“From Modules → Devices → Solutions”

Participants rediscovered Seeed’s journey — beginning with iconic modules such as Seeeduino, the XIAO series, Raspberry Pi carrier boards, and a wide array of I/O and communication modules beloved by the maker community.

This evolution continued into end devices including:

- Long-range LoRaWAN sensor nodes

- Displays and industrial controllers

- High-performance AI single-board computers

- Environment monitoring devices

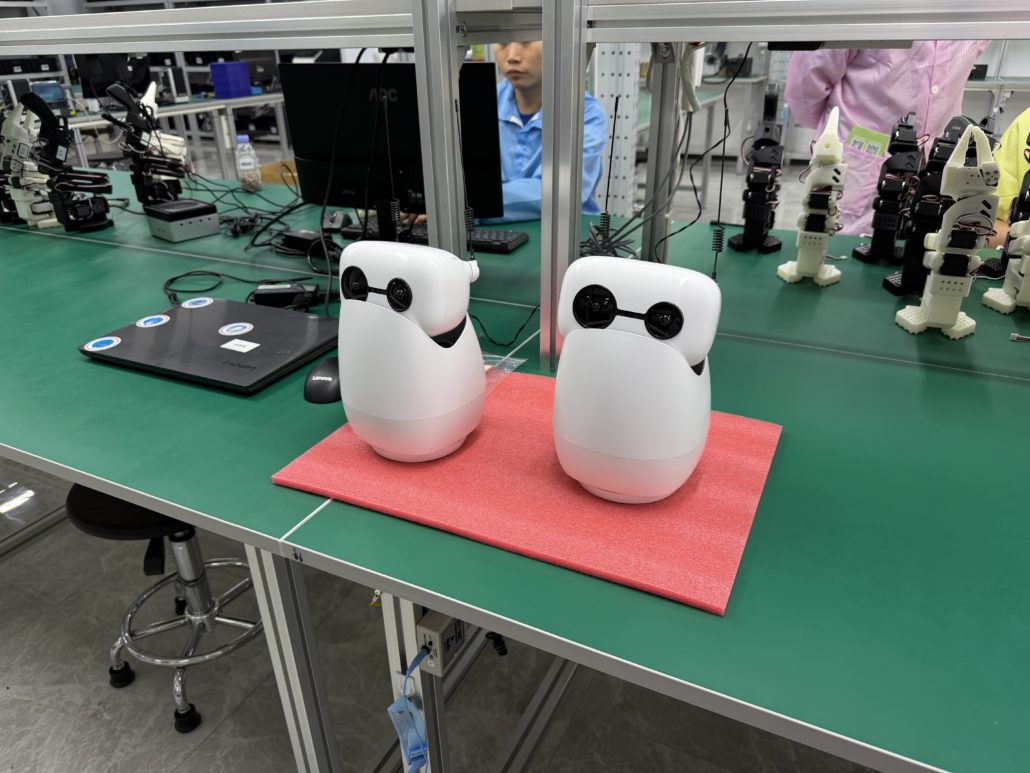

- The recently launched Watcher, now enhanced with “XiaoZhi” AI

Finally, they explored Seeed’s industry-ready solutions for smart agriculture, smart buildings, environmental monitoring, wildfire prevention, and intelligent farming — all built under a philosophy of cost-optimized, market-validated, flexible design.

Understanding the Greater Bay Area Advantage

A highlight of the tour was the enormous Greater Bay Area (GBA) hardware ecosystem map, showcasing how Shenzhen connects with Dongguan, Guangzhou, Zhuhai, and surrounding manufacturing clusters.

Using an ODM robotics project (Reachy Mini, co-developed with Pollen Robotics) as a real example, guests learned how different components originate from specialized towns across the GBA — from CNC structural parts and speaker modules to heat-sink assemblies and battery packs.

Participants gained a deeper appreciation for why Shenzhen remains the global hub for hardware innovation:

- Nanshan & Futian: R&D and semiconductor design

- Bao’an: molding, injection, metalwork

- Dongguan: precision parts and supporting materials

- Shenzhen: full-stack integration, rapid iteration, supply-chain density

This interconnected ecosystem allows Seeed to offer one-stop hardware customization and ensure fast lead times through supply-chain orchestration, inventory planning, and parallel engineering.

Factory Visits: Experiencing the Supply Chain First-Hand

Beyond AMC, participants visited several of Seeed’s long-term strategic partners:

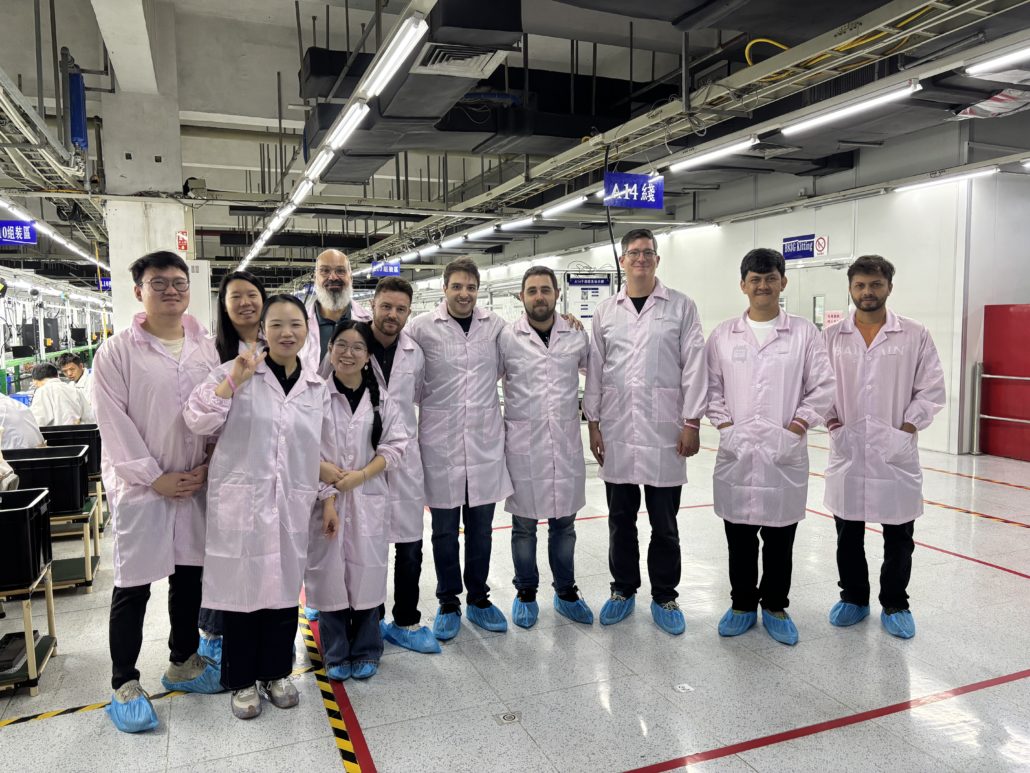

1. GoldTek Technology (Shenzhen) Co., Ltd. –Foxconn sub-factory

A large-scale SMT powerhouse supporting Seeed’s high-volume PCBA needs. Attendees observed advanced SMT automation, quality control systems, and the stringent real-name security registration typical of world-class factories.

2. Shenzhen RPS Rapid Prototype Technology Co., Ltd. -Mould Factory

A deep look into injection mold design, tooling craftsmanship, CNC machining, and how precision molds shape the manufacturing backbone of consumer electronics.

3. Shenzhen Feetech Model Co., Ltd. -Servo Factory

Participants visited Shenzhen Feetech Model Co., Ltd., a globally recognized servo motor manufacturer widely used in robotics, automation, and smart devices.

During the tour, guests explored:

- High-precision servo motor assembly lines

- Gearbox manufacturing and quality inspection

- Motor winding and torque testing

- Reliability and lifespan verification processes

4. Design Society – “Future You: Walking Evolution” Exhibition

To conclude the journey, participants visited Shekou Design Society’s exhibition exploring the dual themes of “Code” and “Soul,” reflecting on human identity, AI evolution, and the future of digital-physical interaction.

Seeed AMC — Agile, Professional, and Built for Innovators

Throughout the tour, Seeed highlighted two core strengths of its AMC:

Agility

- Small-batch flexible production

- Rapid prototyping

- Parallel development workflow

- Quick sample-to-production transitions

- OPL Open Parts Library for fast component selection

Professionalism

- ISO9001-certified manufacturing

- Wind-tunnel testing for environmental devices

- Advanced digital factory management

- Over 3,000 accumulated test solutions

- More than 8,000 SKUs built over 16 years

- 50+ million units shipped globally

Participants gained a clear view of how Seeed defines quality — from R&D reliability design and DFM/DFA reviews to measurable acceptance criteria and full-process QA.

A Day of Learning, Inspiration, and Global Connection

The atmosphere throughout the day was filled with curiosity, excitement, and meaningful conversation. Many makers commented that this was their first time entering Chinese factories and that the experience reshaped their understanding of global manufacturing.

For Seeed, the 2025 Hi Tour represents more than a factory visit — it is a bridge connecting global creators with the power of Shenzhen’s agile manufacturing ecosystem. It strengthens the global maker community and inspires new ideas, collaborations, and future innovations.

About Seeed Studio Fusion

Seeed Studio Fusion is a global one-stop online platform for PCB manufacturing & assembly, and hardware customization. Whether you need prototyping, mass production, custom solutions for open-source products, or the transformation of your creative ideas into profitable products, Seeed Studio Fusion can meet your requirements.