How BLE + LoRaWAN Tracking Works Best in GNSS-Challenged Mining Areas

Tracking miners and equipment is tough. Mining sites are massive, uneven, and packed with structures and areas where the sky isn’t visible, causing GNSS coverage to fail. In areas where GNSS becomes unreliable, blind spots form easily, and during emergencies, those blind spots become a serious safety risk. Solution providers need a more reliable real-time personnel tracking method that can still transmit urgent alerts like panic button presses without depending on heavy or complex infrastructure.

This blog explains why more solution providers are choosing hybrid BLE + LoRaWAN tracking for GNSS-challenged mining environments.

Why No Single Technology is Enough

Mining sites aren’t uniform. Workers move between open outdoor areas where GNSS works well, and enclosed or unobstructed areas where the sky isn’t visible and GNSS becomes unusable. BLE, on the other hand, performs reliably in these GNSS-challenged zones, but it is not designed to cover long distances. Both GNSS and BLE rely on LoRaWAN to transmit positioning data. This is why a single positioning method cannot cover every part of the mine. Only a hybrid approach ensures visibility as workers move between different environments.

Read our full comparison of BLE, UWB, GPS, and WiFi for safety tracking.

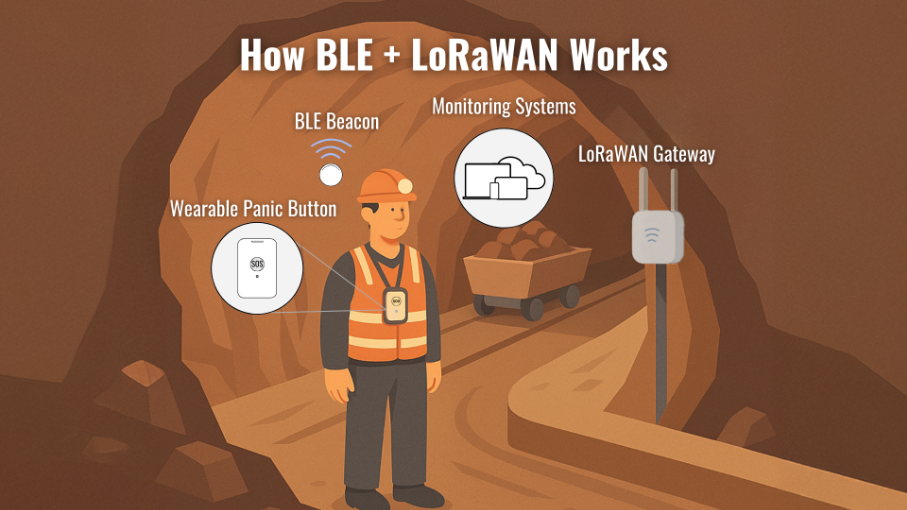

How LoRaWAN + BLE Work Together

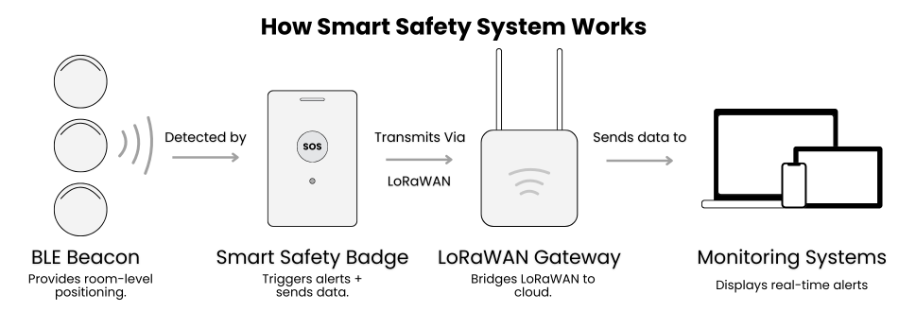

LoRaWAN provides long-range, low-power communication across large sites. When gateways are placed correctly, a single gateway can cover wide or remote areas. It also handles critical alerts, such as panic button presses, without relying on cellular connectivity. When gateways are positioned correctly, LoRaWAN maintains stable reporting with minimal infrastructure.

BLE complements this by providing reliable short-range, zone-level detection wherever beacons are placed. This can include machinery zones, walkways, shelters, and any location where additional visibility is needed. Depending on the beacon layout, BLE can capture worker presence, movement patterns, and local context in areas where GNSS performance drops. Typical BLE coverage ranges from around 5 to 30 meters in complex environments.

Together, BLE provides the local accuracy, and LoRaWAN serves as the communication backbone that carries all updates, including location data and emergency alerts, to the cloud. This hybrid method reduces coverage gaps and offers a more practical way to maintain visibility across GNSS-challenged mining environments.

Addressing Common Concerns About Technical Reliability

● How does the system stay reliable in mixed mining environments with obstacles?

Mining sites are challenging for any wireless systems, but using BLE and LoRaWAN together helps reduce these issues. BLE provides accurate zone detection in defined areas, while LoRaWAN simply uploads all positioning data, whether it comes from GNSS or BLE, and keeps reporting stable across wider or unobstructed zones when gateways are positioned correctly.

● Can it keep reporting accurately when workers or equipment move around?

Yes. BLE captures zone entries as workers pass beacons, and LoRaWAN transmits scheduled updates as they move across different parts of the site. If BLE is not detected temporarily, the badge still continues sending its regular reports through LoRaWAN, ensuring continuous visibility.

● How does the network stay consistent across different site conditions?

LoRaWAN uplinks are lightweight and optimized for long-range communication. Adaptive Data Rate (ADR) automatically adjusts transmission settings based on the surrounding environment, helping maintain more stable reporting in both open and obstructed areas.

Click for more technical reading on LoRaWAN in mining environments.

Build Your Solution with Seeed Studio

Every deployment is different, and we offer a fully customisable hardware stack to match your site’s workflow. Our hybrid BLE and LoRaWAN setup includes a wearable panic button, BLE beacons, and LoRaWAN gateways. The system can be tailored through device configuration, reporting logic, and deployment design to meet the needs of different mining environments. For solution providers deploying BLE LoRaWAN mining tracking systems, hardware flexibility is critical.

If you’re building or upgrading a mining safety solution, we can help you configure the right hybrid setup. Contact us today.