How Mines Track Both People and Assets Using One LoRaWAN Network

Why Traditional Tracking Fails in Mining Environments

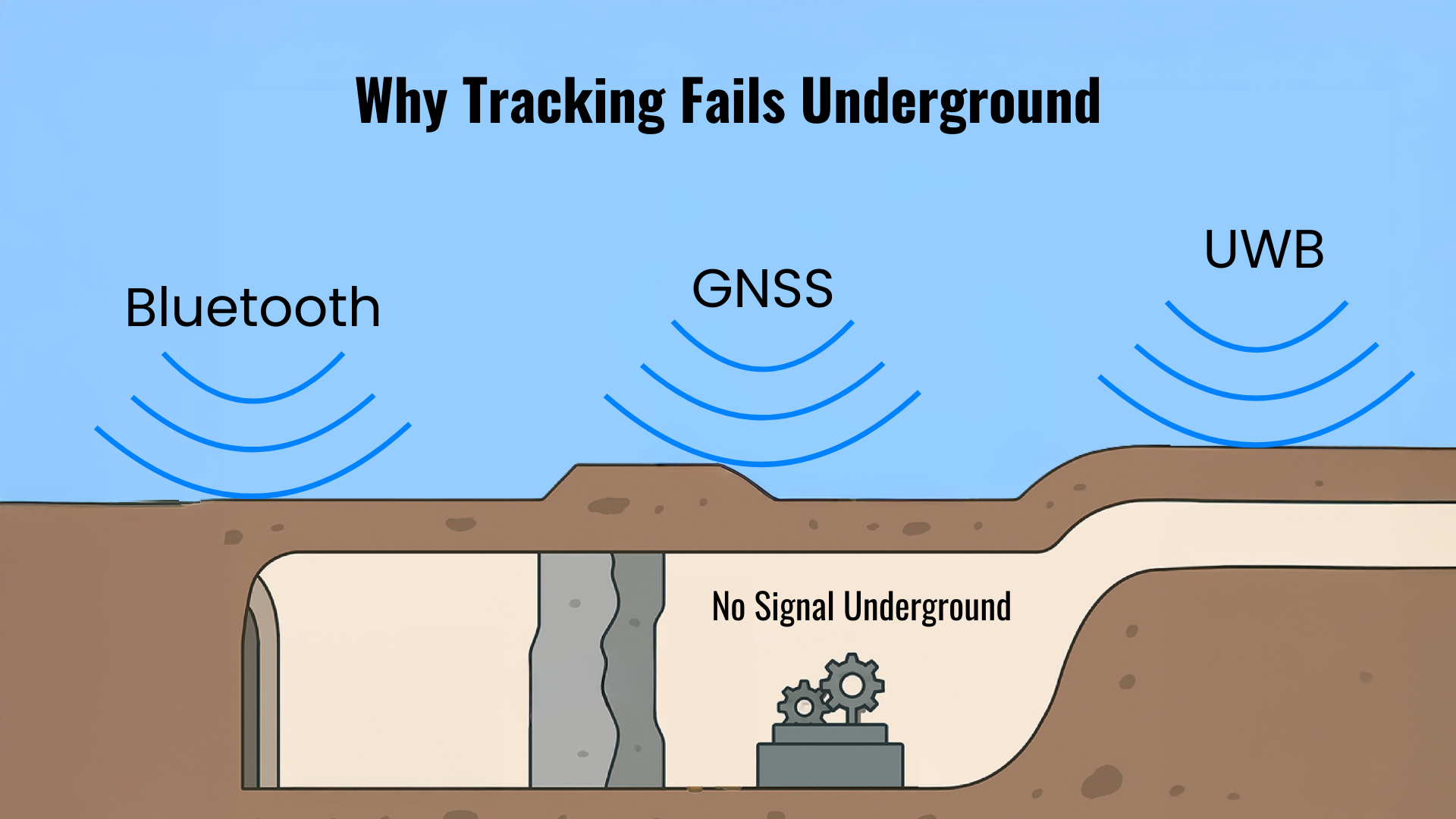

LoRaWAN mining tracking is designed for environments where traditional tracking systems fail. Underground mines block GNSS, cellular, UWB, and conventional Bluetooth signals with rock, metal structures, and heavy machinery.

On top of that, many mining operations are also highly dynamic. Sites are often remote and temporary, with infrastructure that must be deployed quickly, relocated frequently, and expanded as operations change. Different operational zones can all exist within the same site, each with very different coverage conditions.

Because of this mix of physical and operational constraints, tracking failures in mines are rarely caused by poor planning alone. The environment itself works against traditional tracking approaches from the start.

Why Personnel and Assets Need Different Tracking Approaches

Tracking People in Mines

Tracking people in mines is driven primarily by safety and compliance rather than efficiency. Devices need to be comfortable enough to wear throughout shifts and compatible with different operational settings, otherwise workers are less likely to wear them consistently. Personnel tracking often supports emergency alerts, where dependable operation matters more than long battery life or rugged hardware. This is why compact wearable trackers like the T1000 are typically used for personnel tracking in mining environments.

Tracking Vehicles, Tools and Heavy Assets

Tracking vehicles, tools, and heavy assets in mines is driven by loss prevention and operational continuity rather than real-time precision. These devices are mounted on equipment rather than worn and are expected to operate over long deployment cycles with minimal maintenance, prioritising durability and reliability over size or comfort. Asset-focused trackers such as T2000 fit this role, with anti-theft or tamper alerts to flag unauthorised removal.

Why LoRaWAN Is the Backbone That Makes This Work

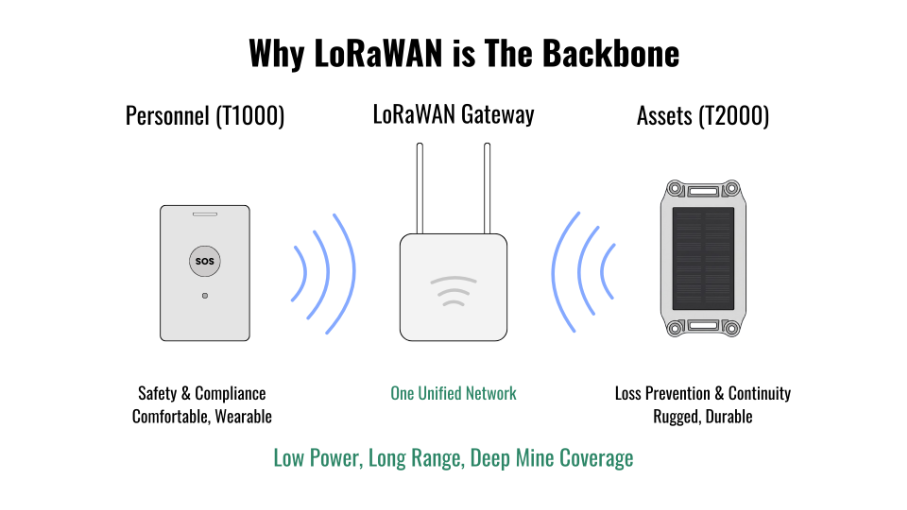

Supporting both people and asset tracking at scale requires a network designed for long-range, low-power communication across large sites. LoRaWAN works well in mines because its longer wavelengths provide better coverage across environments where obstacles and distance would break short-range technologies. Its low-power design also reduces the need for frequent battery charging, which is critical in environments where maintaining infrastructure is costly or disruptive.

LoRaWAN also allows both people and assets to operate on the same network. A single infrastructure can support different tracking roles without deploying parallel systems, reducing complexity and overall cost. Beyond tracking, the same network can also support other site-wide use cases, making LoRaWAN a practical backbone for mining operations that need flexibility as sites expand or change. This is why LoRaWAN mining tracking has become the backbone for large underground operations.

For a deeper comparison of underground tracking technologies, see our breakdown of LoRaWAN, GNSS, UWB, and Wi-Fi.

Why One-Device-Fits-All Tracking Always Breaks

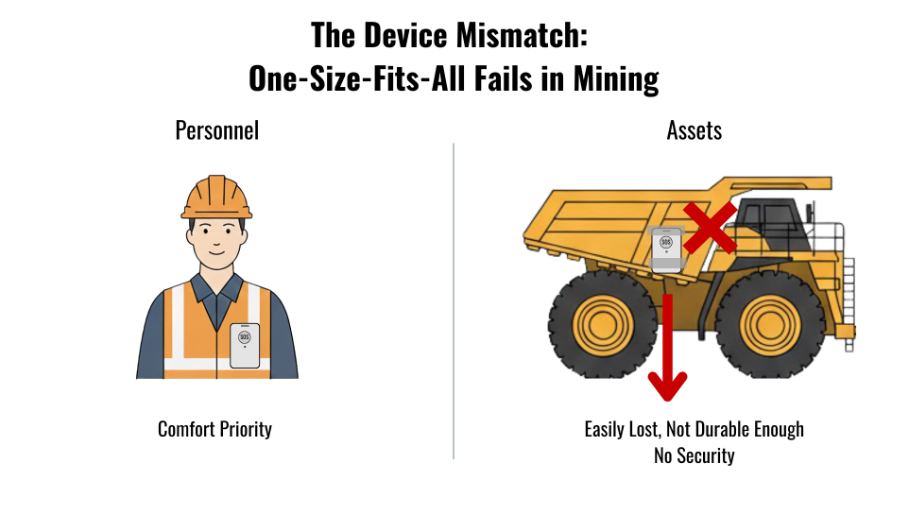

Standardising on a single tracking device often looks appealing on paper. It simplifies procurement, reduces the number of devices to manage, and appears cheaper upfront. In mining environments, however, this approach rarely holds up in practice.

Wearables are not built to meet asset-level security needs, while asset trackers are often too large and intrusive to be worn by people. When devices do not fit the job they are assigned to, adoption drops and blind spots emerge, especially when reliability matters most. In mining operations, those blind spots become especially dangerous during incidents, when accurate and trusted tracking is critical.

A Practical Way to Deploy Tracking in Mines

This is the approach behind Seeed’s LoRaWAN tracking solution. Personnel tracking is handled using lightweight wearable devices like the T1000, designed with a compact form factor suitable for long shifts. Assets are tracked using devices such as the T2000. Both operating on the same LoRaWAN network supported by BLE beacons and LoRaWAN gateways.

In unpredictable mining environments, Seeed’s solution is fully customisable to fit different deployment site layouts, tunnel structures and operational requirements. Instead of forcing a one-size-fits-all system, deployments are designed around how your mine actually operates.

Design a LoRaWAN tracking deployment that works for your mine. Talk to our team to evaluate your site and plan a tracking architecture tailored to your operation.