Why Are Printed Circuit Boards Usually Green In Color?

I see most printed circuit boards are green in color. I’ve seen some blue and yellow boards, but not so many – so I have a question: Why are most PCBs green?

The above question is not only asked by electronics hobbyists but also questioned by engineers, so today let’s unravel the mystery.

What the green part of a circuit board is

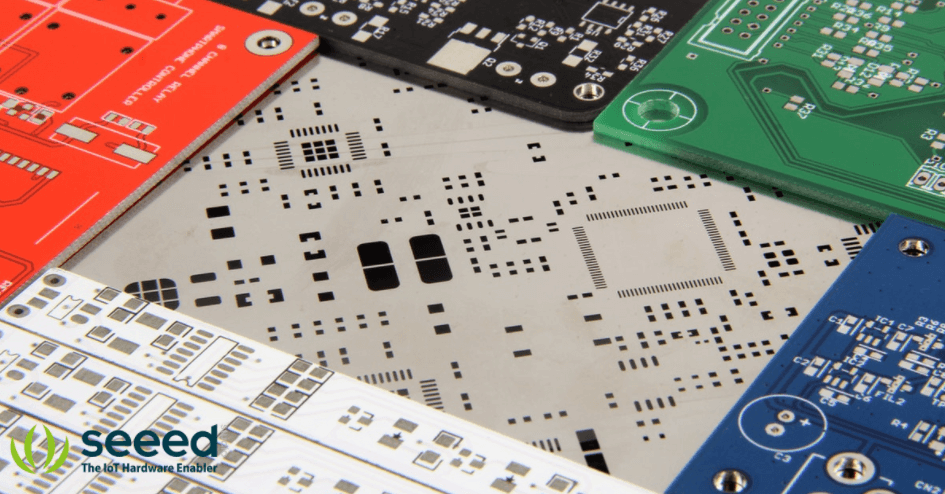

A ‘green’ printed circuit board is not actually green all the way through. The only green part is the outer covering of resin called the solder mask or solder resist/oil. This is a hardened resin with colored pigments that is applied to the boards in a silkscreen fashion. The purpose of solder mask is to protect the electronic traces underneath from moisture and dust and to control the flow of molten solder. The actual core of a typical FR-4 circuit board is a plain, dull, yellow color, but the solder mask can come in many colors such as blue, red, yellow, black and white. Even more exotic colors can be found for the extravagant such as orange, pink, purple, matte versions and even mixed color boards. So, the question remains, why green?

Top Reasons Why Most PCBs are Green in Color

1. Green can relieve visual fatigue and aid in inspections

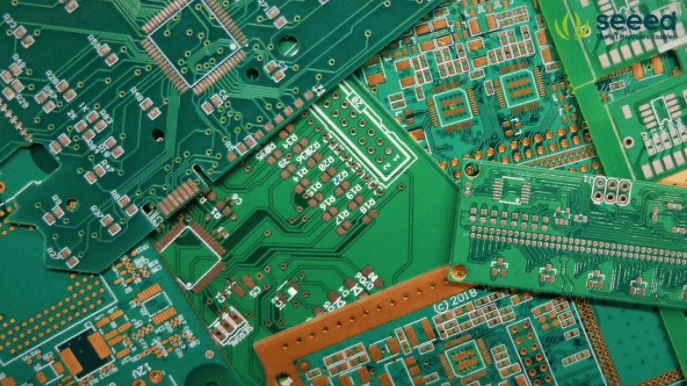

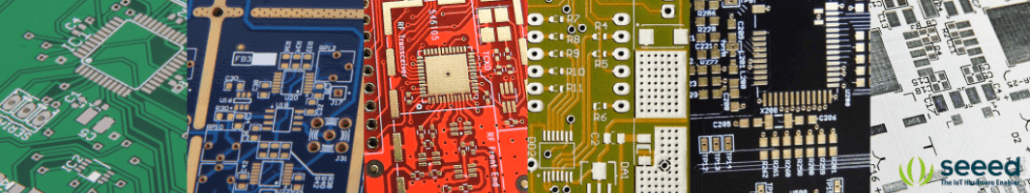

In the early days, due to technological restrictions, quality inspections relied on workers manually checking the boards with their bare eyes. Squinting at tiny circuits all days is tiring work, but neurologists and psychologists agree that the wavelength of green light has relaxing effects on the body and can reduce fatigue. Additionally, they have found that the sensors in human eyes, or cones, are most sensitive to green light. Therefore, the contrast is greater between the circuit traces, pads, silkscreen printing and empty spaces. Just by observing the boards from the outside, one can easily identify defects in the outer layers. Compare the below images of green boards to other colors such as blue, yellow or even black and white. With higher contrast, errors are easier to spot.

Of course, nowadays PCB manufacturers use flying probe techniques and Automatic Optical Inspection (AOI) for these tasks, which is very effective in spotting errors. But there is another very important technical reason why most PCBs are green.

2. Green solder mask is physically superior

Due to the traditional aspect of using green pigments, R&D into making better solder mask oils focused on the standard green color. The actual chemical pigments used influence the performance of the resin during application and in the field. When demand is pushing form factors to their limits, no one cares about having pink boards. As a result, green solder mask now has superior properties compared to other aesthetically orientated colors.

Most prominently, commercial green solder mask is the only available color that can reliably produce solder mask dams of 0.1mm (4mil). Next up is red, yellow and blue that can produce 0.12mm dams and then black and white which can typically only achieve 0.15mm. Solder mask dams are vital for ICs and fine pitch components since they are valuable in preventing solder bridges from forming.

Did you know?

The green in most green soldermask oils comes from chlorine. Chlorine, along with Bromine, which is found in PCB substrates, are halogens which have a severely detrimental impact on health and the environment if disposed of inappropriately. Halogen free soldermask oils and substrates are available. For halogen free solder mask, you could just switch to another color.

3. Bulk = Cheap

Solder mask is typically applied using silkscreen techniques. A large blob of oil is dragged across a screen mesh with the circuit board underneath. The circuit board is removed for curing, and the next board goes under the mesh. But hey, hold on, I want another solder mask color. Well, then you have to remove the excess solder mask oil and wash the silkscreen before applying the new color. Otherwise, a silkscreen station is needed for each color. Furthermore, for white or lighter solder mask shades, you’ll also need another station for the black silkscreen ink. The oils also don’t keep for very long. If you find that one color is not particularly popular, the chemicals will be wasted and efficiency will be impaired.

Similarly, some factories will not accept certain combinations of PCB features with colors other than green, since green is by default the most popular color.

Consider this: typically, in a quickturn PCB fab house, many designs from various orders are grouped together on one panel (panelized). This way, they can make the most out of PCB real estate and reduce waste. But there are many processes that require the entire panel to be processed the same, like surface finishes and plating for castellated holes. So all boards on a particular panel must have the same requirements.

By adding more and more specific features, the factory is more likely to end up with insufficient designs to fill a panel at one time. Adding factors such as solder mask color or board thickness into the picture multiplies the number of possible combinations, multiplies the waste and therefore increases cost. Even if the factory is willing to undertake your specific request, you may end up paying for the cost of the entire panel. So by restricting certain combinations of colors and features, factories can keep costs down.

Not to mention, developing a new solder mask oil that performs well as an electrical insulator, applies and adheres evenly, cures well and looks visually appealing is not a simple process. As such, expect to pay a premium for special requests like matte beige.

So there are many reasons to love and not to love green. Which do you like best and why? Join our ongoing poll to pick your favorite below. Seeed Fusion’s PCB fabrication service offers a good range of solder mask colors to suit your prototyping palette from deep-sea blue, Ferrari red, sunshine yellow, slick black, pure white and of course good ol’ green and at no extra cost.

Now, we have Matte Black solder mask oil available for all PCB production services for that extra high-end look.

Get an instant online quote now