Seeed Fusion PCBA Series 2: The Tour Continues…

In the first entry, we introduced Seeed’s SMT Assembly line, and we took a look at the paste applicator, pick and place machine and reflow oven. You may think that’s all there is to PCBA but there is more. We will cover through-hole assembly and testing options here.

Through-Hole Component Assembly

To solder large volumes of through-hole components, assemblers traditionally used wave soldering machines that run the boards across a molten bath of solder. But this method may not be suitable for double-sided mixed assembly boards, and continuously maintaining the molten bath is both economically and environmentally inefficient. So, to solder the many connectors and pins that typically go into development boards, Seeed has opted for a selective soldering method. Plugging Grove connectors into the Seeed Grove Mini Fan v1.1 boards

Plugging Grove connectors into the Seeed Grove Mini Fan v1.1 boards

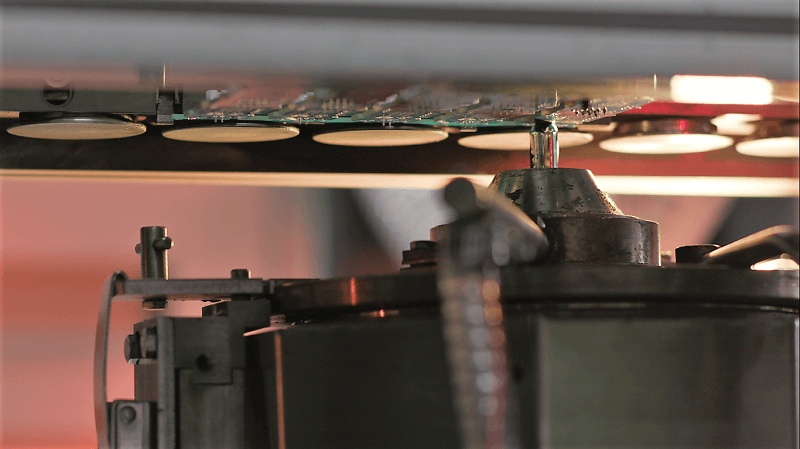

This ominous-looking piece of equipment is the selective soldering machine

This ominous-looking piece of equipment is the selective soldering machine

The selective soldering unit moves up and applies solder from below

The selective soldering unit moves up and applies solder from below

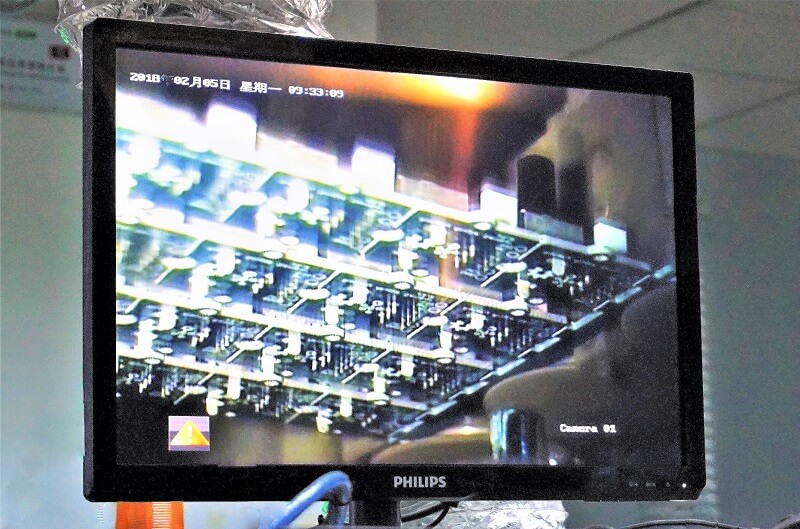

The entire process can be monitored from a display above the machine

The entire process can be monitored from a display above the machine

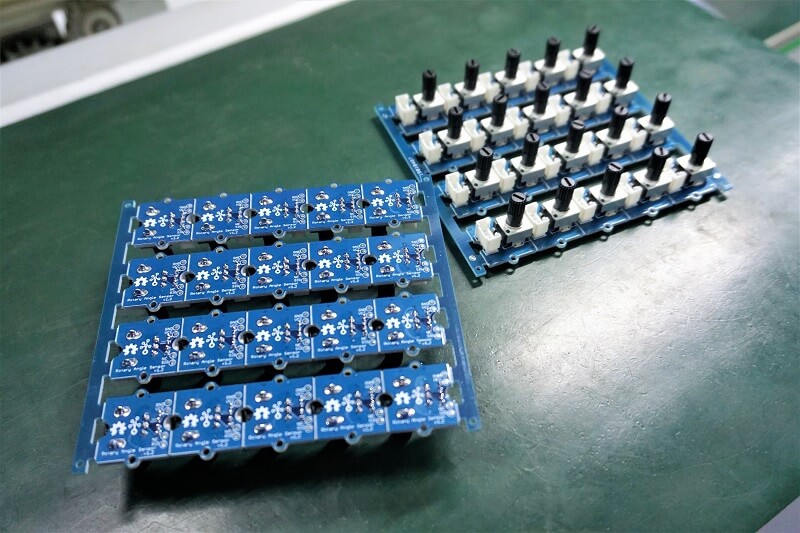

Perfectly soldered joints every time!

Perfectly soldered joints every time!

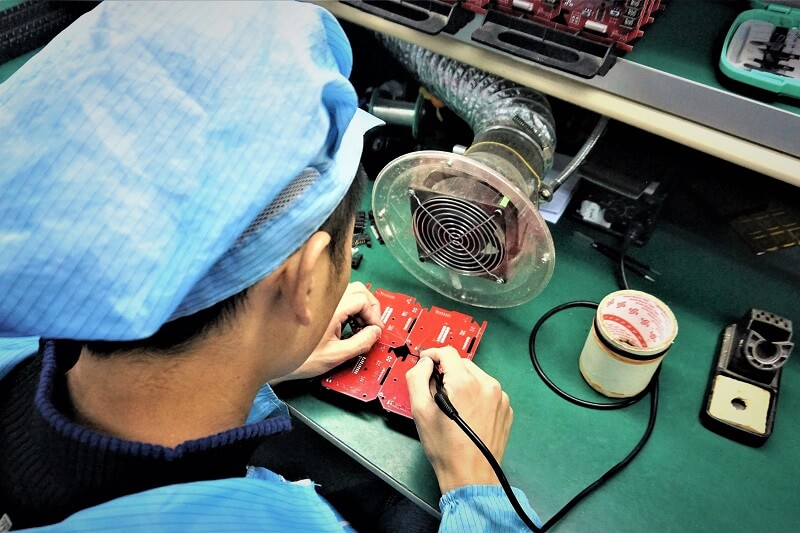

Inspection and Re-working

After all soldering is completed, each board is cleaned and again carefully inspected for soldering defects such as tombstoning or misalignment from the reflow oven. Any errors are identified, and the boards are sent to the re-working station to be corrected manually. Technicians are on hand to do any touch-ups

Technicians are on hand to do any touch-ups

Testing

After visual inspections are completed, other more in-depth tests are carried out if required. Seeed can arrange various tests including functional tests to ensure your device operates as expected, mechanical tests such as temperature and humidity tests, In-Circuit-Tests (ICT), AOI and X-ray inspections for example. Choose functional testing and every board is tested

Choose functional testing and every board is tested