SenseCAP Devices Enabling Sophisticated Fermentation Control in Baijiu Distillery

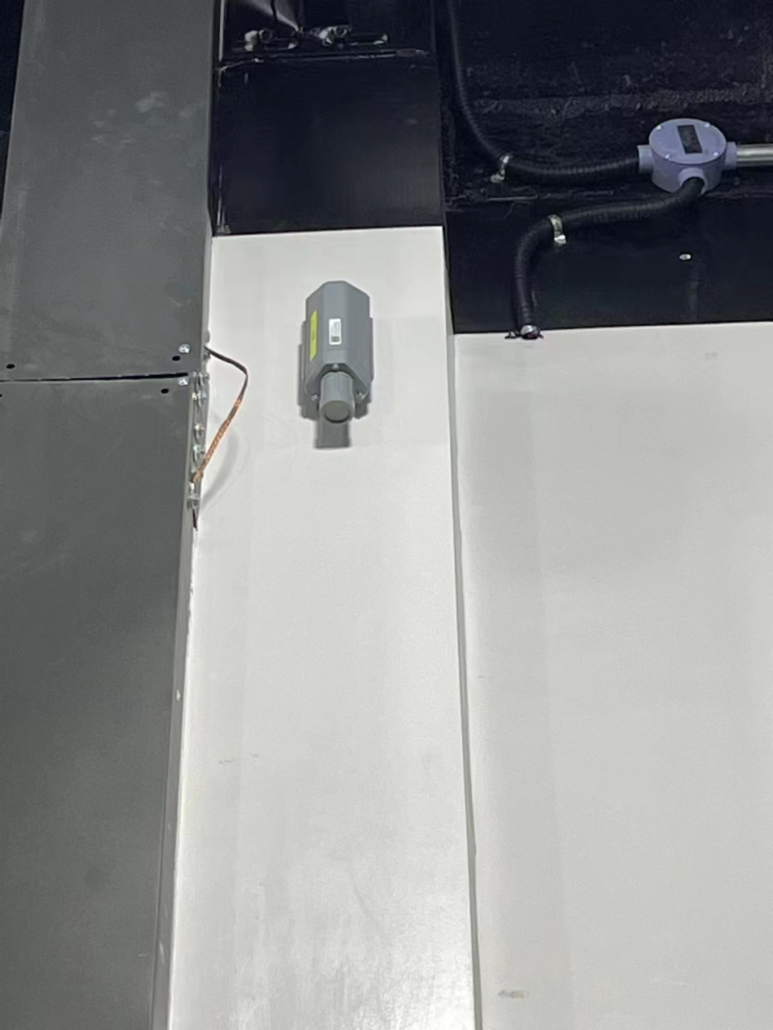

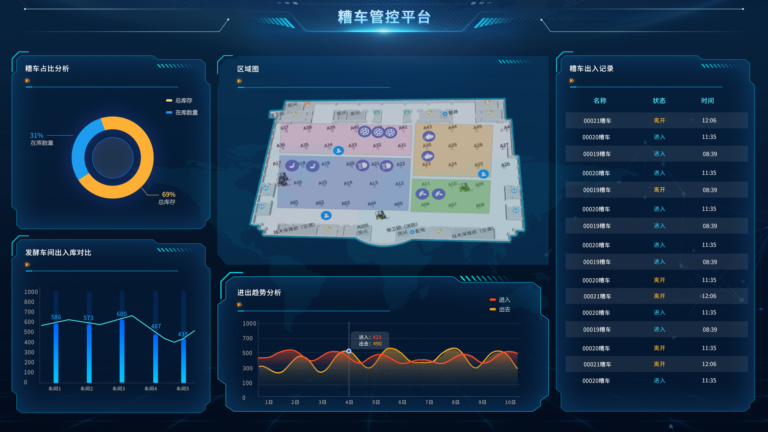

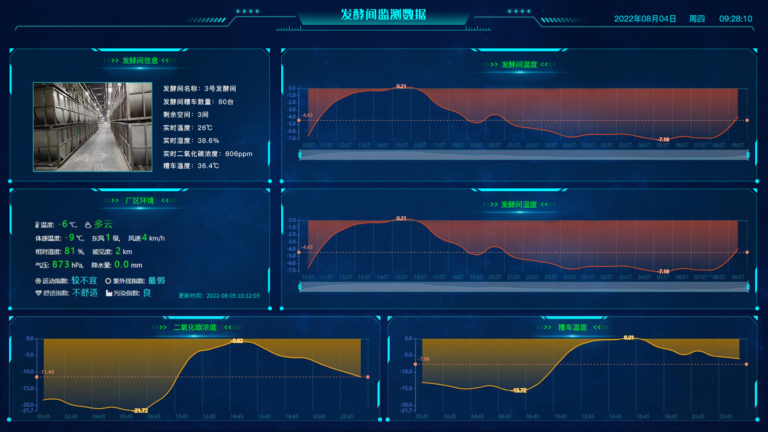

To address the need of digital transformation in traditional Baijiu brewing industry, Seeed Studio has helped to build up a Smart Fermentation Management and Control Platform for a Baijiu manufacturer in Shanxi, China.