[Covid-19 Series] Face-Mask Disinfection Device Using UV-C and Dry Heat by Team Needlab

Message from Seeed: We are starting a series of articles featuring projects that have arisen recently in response to the shortage of personal protective equipment and other medical supplies in combating Covid-19. These projects are mostly collaborative community efforts, and are constantly evolving and upgrading as a result of open discussion on online platforms. While some of the science or technology in these projects are not yet 100% proven to be effective or sufficient for their purpose, we applaud the spirit, ingenuity and research behind these projects, which reaffirm the belief that makers can make immense impact at times like this. The projects we feature do not necessarily contain Seeed products, however we will constantly review and source parts for certain projects, to be made available on seeedstudio.com

When the Covid-19 outbreak forced L’École LDLC , a school focused on digital education in Lyon, France, to shut down temporarily in March, its pedogogical director Jean Noël Lefebvre found himself at home wondering how he could contribute to our shared fight with this global pandemic. An engineer and an entrepreneur, with years of STEAM mentoring experience, Jean Noël quickly found his community to serve. As there was a severe shortage of the PPEs (personal protection equipment) for medical professionals in local clinics, nursing homes and public workers, he and his collaborators Pierre-Gilles Levallois and Sameera Chukkapalli at Needlab in Barcelona, Spain, came up with the idea of a face mask disinfecting device, which would allow single-use face masks to be disinfected for re-use using a combination of ultraviolet germicidal irradiation (UVGI) and dry heat.

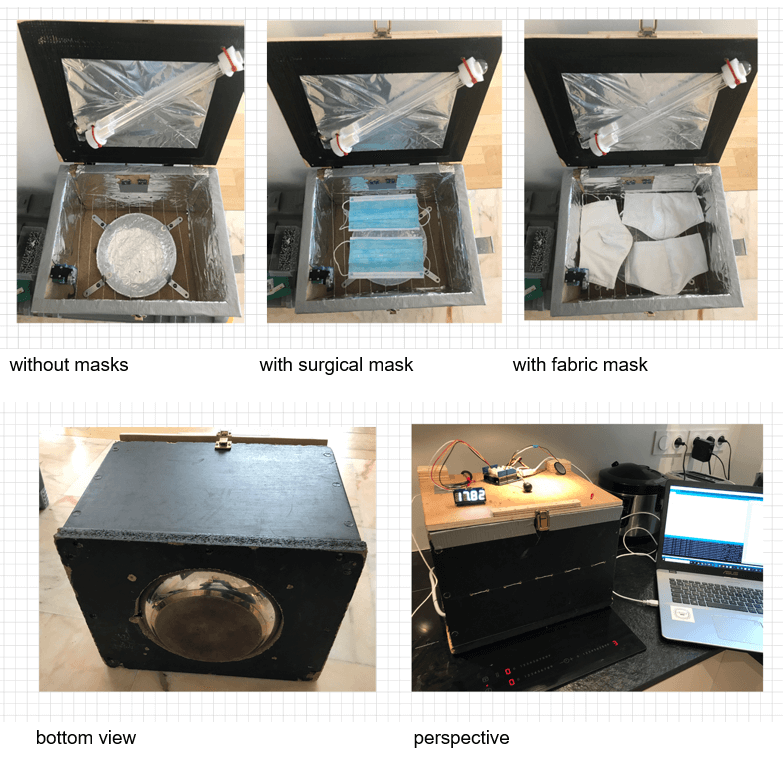

While hospitals and research facilities may have implemented such mechanisms for disinfecting masks using standard tools, these tools are not available in smaller clinics and nursing homes, or in more vulnerable parts of the world. Jean Noël and his team aimed to design and prototype a solution that is low budget, portable and could be fabricated at home or in any local Fablab or makerspace. They came up with an Arduino-controlled device that can be placed on induction stove for heat, and enclosed in a box that contains a UV-C lamp.

Basic Structure and Mechanism

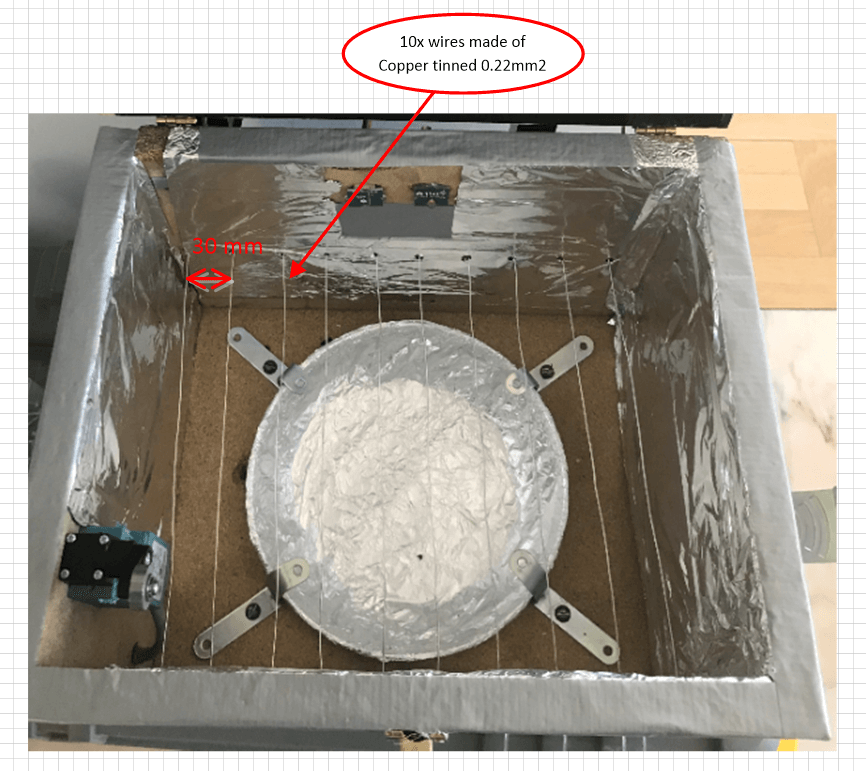

According to essays that the team had studied, the SARS-CoV-2 starts to lose infectivity after being incubated starting at 56°C, or 132.8°F for various amounts of time, and is almost completely inactivated at 75°C/167°F for 30~45 min. In the end, given different considerations, the team decided to set the heat exposure of the protocol to be used with the device at 65 °C/149°F for 30 min. In their prototype, this heat is provided by the induction cooktop. The bottom of the device sees a frying pan that protrudes slightly, that would allow the device to be placed directly on the stove top.

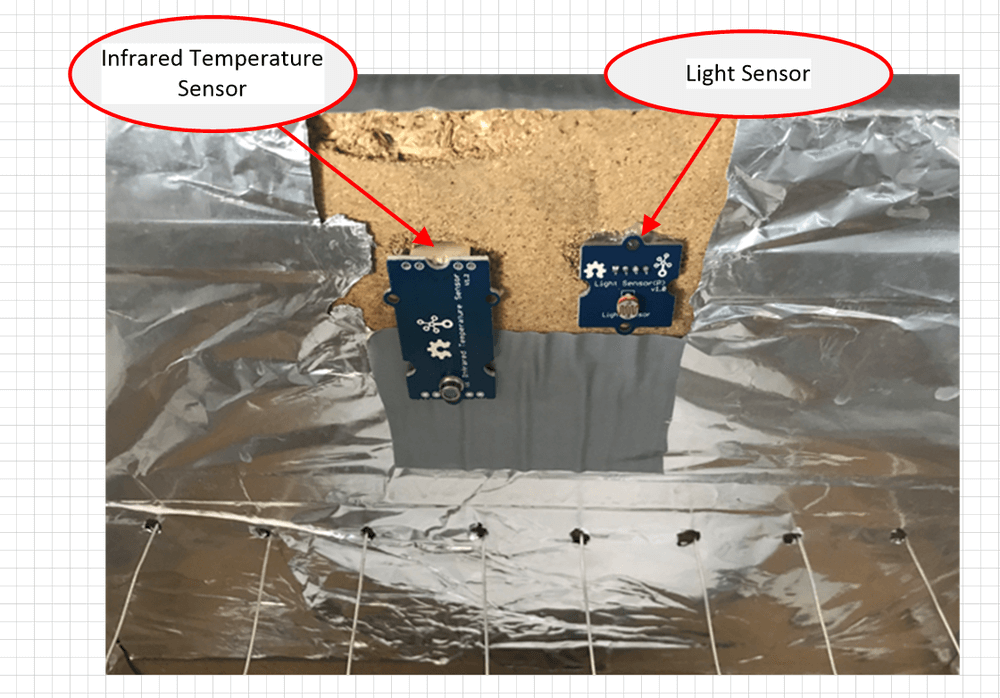

Inside the box, the masks would be placed directly on the wire rack that is fixed over the frying pan, while Seeed’s Grove infrared temperature sensor and light sensor are placed on one of the walls.

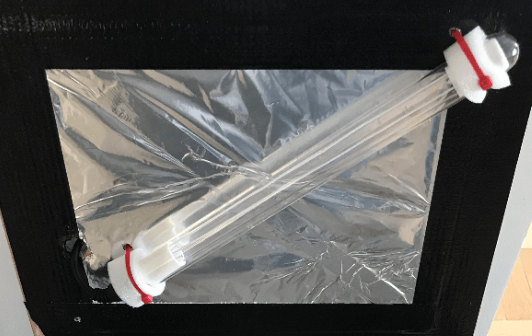

For the UV-C source in this device, the team used an 11 W lamp bulb extracted from an aquarium kit. It was then mounted to the top cover of the box. Jean Noël and team stress the danger of UV-C on eyes and skin in their documentation! So be careful! Jean Noël describes the reason for using UV-C, in addition to the dry heat, is the same as having both the seatbelt and airbag in a car — double measures for double protection.

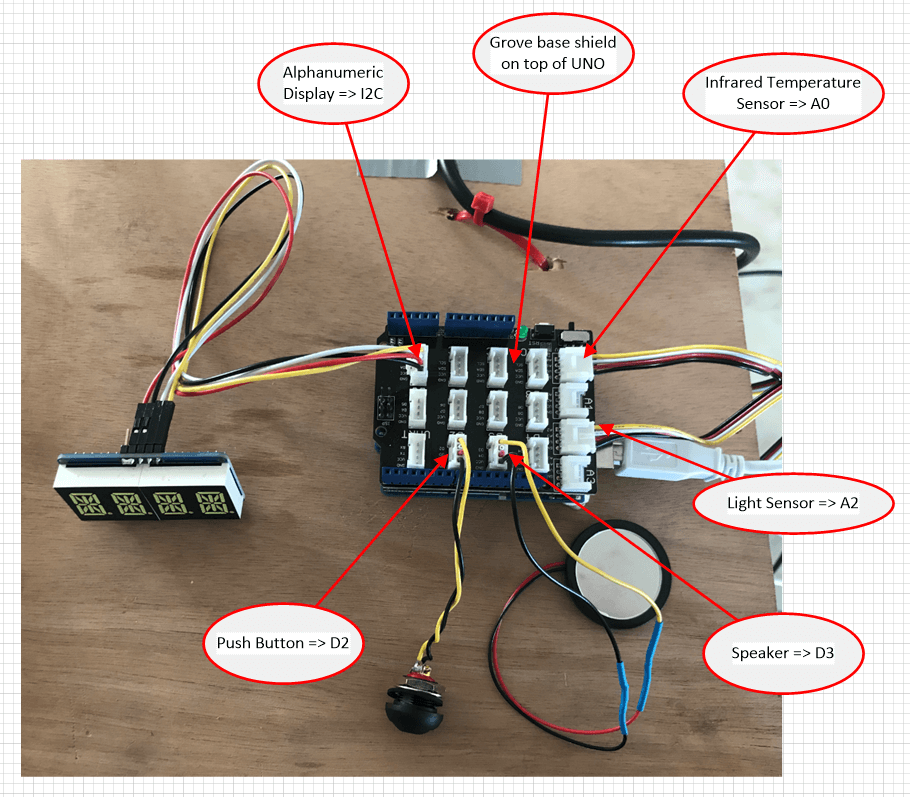

Outside, on top of the box, is the Arduino set-up. An Arduino Uno was used with a Grove base shield that would connect to the sensors placed inside the box. An alphanumeric display is on hand to show temperature and time, along with push button for control, and a speaker for sounding alarms.

That’s a basic description of the physical device, and full Arduino source codes along with detailed explanation of the project and user manual can be found through links at the end of this article (you are almost there). The device can be used for both surgical masks and homemade fabric masks, though it has been suggested that surgical masks should not be used after 3~5 disinfections.

What’s Happening with the Project Now?

Jean Noël is happily using his device to disinfect fabric masks, and enjoys the benefit of not having to dry if the fabric masks were to be washed. He is also in the process of having this prototype tested by a reputable lab, so its effectiveness could be certified. In the meantime, he and Team Needlab are working on the version 2.0 of the device, including optimization of the dimensions so that a bigger box can be made for disinfecting 3D-printed face shields, complete with design CAO files for laser cutting and/or CNC machines. They will also propose different selections of sensors and displays to facilitate the Arduino setup, so that people can choose one that’s more accessible to them. So, more good things to come. Thank you Jean Noël and Team Needlab for the amazing work!

Links to the Full Project

Hackster: https://www.hackster.io/needlab/face-masks-disinfection-device-needlab-3ed2f5

Arduino: https://create.arduino.cc/projecthub/needlab/face-masks-disinfection-device-needlab-3ed2f5?f=1

Needlab: http://www.needlab.org/face-masks-disinfection-device

Stay tuned for more project stories. Questions? Comments? Got a Covid-19 project to share? Please email Monica at [email protected] because she is waiting at home 🙂