Inside Made in China: Dongguan Factories Welcome Fablab Barcelona

Hello community, and welcome back to our third volume of Inside Made in China. For those of you who are new to this series, it is all about how things are “Made in China”. We’re curating series posts to tour you around online to local factories in Dongguan, where sits our new Chaihuo x.factory Dongguan. We regard it as an interface for the global maker community to the local manufacturing system, with the aim to open up the local manufacturing resources to the global maker community, lower the manufacturing barrier and help you to gain a better understanding of the local manufacturing ecosystem.

For the third entry in the series, we have special guests from Spain in the form of the FabLab Barcelona students. Lead by an old friend of Seeed, Tomas Diez and co-director Oscar Tomico; the students are in the early stages of the FabLab component of their Masters in Design for Emergent Futures course at the Institute of Advanced Architecture of Catalonia (IAAC) in cooperation with ELISAVA.

The students come from mixed academic backgrounds and from an even bigger mix of countries, but all have come together to learn about some of the most dynamic innovative ecosystems in the world: Shenzhen and Dongguan.

In this Chaihuo x.factory Hardware Innovation Tour (HI Tour), we cover the lifecycle of hardware manufacturing essentials from enclosures and PCBs, to finally putting them together in a

First stop, Strongd Molding. Strongd molding is a big name in model making for prototyping and large-scale production for the likes of Jaguar, TCL, and Huawei. From car bumpers, stainless steel machine parts, flat-screen television sets to TV remote controls the size of television sets. Is there anything they can’t make?

Capable of plastic and metal CNC machining, 3D printing, injection molding and vacuum casting, Strongd boasts 22 CNC milling and turning machines, 12 monolithic injection molding machines and a vacuum casting workshop for trialing small batches of plastic parts.

Plastic CNC milling in action

Seeing all the workers in the factory, students were interested in the level of automation in the factory. To that, business manager and guide, Tony replied that about 90% is automated largely thanks to the computer-controlled machines. Some manual work is still required though, mainly for prototype runs, machine maintenance, and post-processing.

Injection molds

Xunjiexing

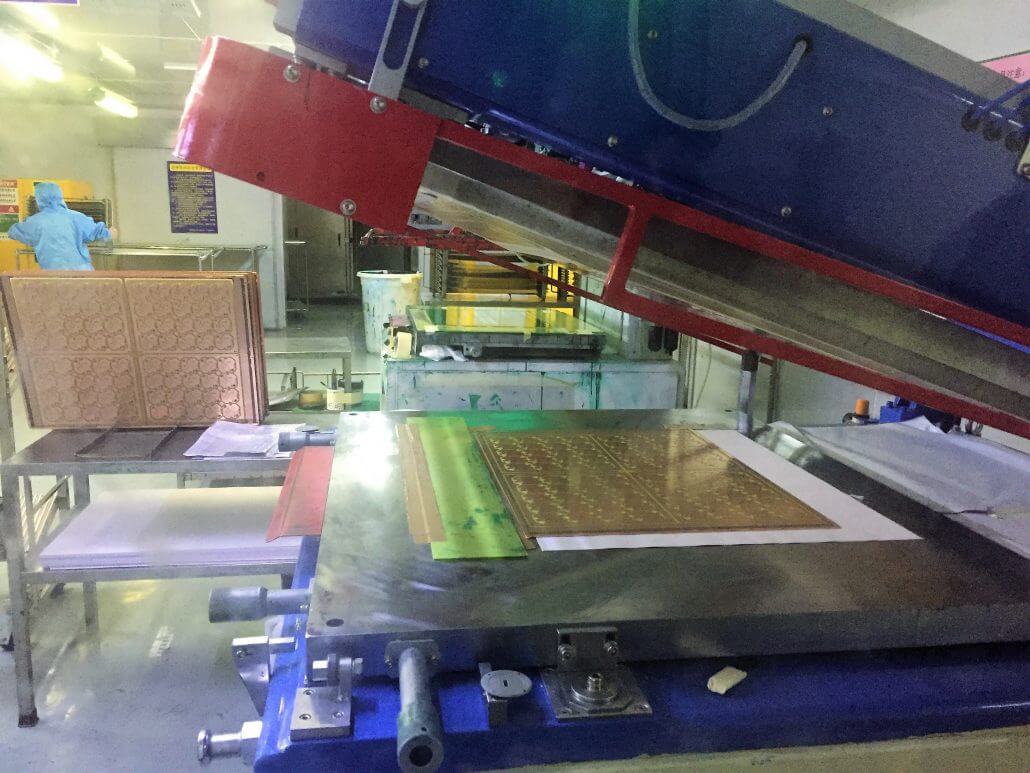

Next stop, a new factory in the series, Xunjiexing printed circuit board manufacturer.

Xunjiexing focus on premium PCB fabrication. They have over 100 CAM engineers providing 24/7 technical service and only use leading internationally recognized brands for materials and machines, including SHENGYI laminates for standard boards and Taiyo solder mask oils, and utilize the latest film free printing technology.

Having only started the FabLab course, many of the students were clueless as to the technical details, but director Mr. Zhang was keen on showing off the factory’s capabilities.

Vanke Smart Construction Site

After a filling lunch, we took a trip to the Vanke smart construction site. Vanke

Practices include dousing the site with a water cannon to control the spread of dust, sound sensors to monitor noise pollution, use of LED spotlights and wall constructions consisting of over 7 independent layers for insulation and fire safety, as well as providing a sound support structure.

The practicing architects and students in the group were keen on finding more about new Chinese construction practices and technologies.

The VR experience demonstrating the consequences of not paying attention to safety guidelines gave the students a good scare.

Chaihuo x.factory Dongguan

Final stop, x.factory. No better place to sit back and enjoy a coffee after a long day than at Chaihuo x.factory Dongguan. Opened in back in October, this new area serves as both a makerspace and an exhibit of x.factory members’ projects. There are a wide variety of machines and equipment, designated work and communal areas, and a forum for presentations and talks.

The exhibition room with x.factory projects including CitizenQ

Art pieces made of old automotive parts

Checking out samples of materials cut using a water-jet cutter. Cutter coming soon to x.factory Dongguan!

This factory HI (Hardware Innovation) tour is a customised service provided by Chaihuo x.factory Dongguan and so if you have any factory visiting inquiries or you want to make use of innovation and manufacturing resources gathered by the x.factory community to transform your project from 0 to 1, Please email us at [email protected]