Seeed Fusion Releases New Design For X Service!

More often than not, many products fail at the manufacturing stage and time is wasted to go through many iterations to get it right. We have seen many customers submit PCB Designs, only to become frustrated at finding out that their designs are defective or not manufacturable due to design errors. Failures, delays and ultimately, frustration can be attributed to anything from lack of space on the PCB, poor component placement, or lack of attention to manufacturing capabilities and tolerances. These failures waste a lot of precious time and money during product development, resulting in project delays and delayed product releases among many other inconveniences.

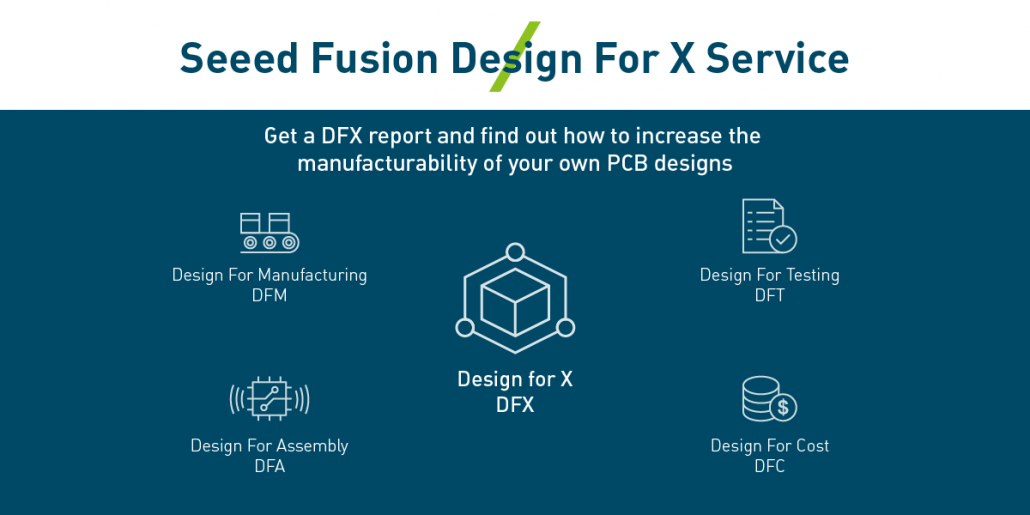

To help remedy this, we are excited to bring you our expertise in the new Seeed Fusion Design For X (DFX) Service!

Truth to be told, this service isn’t entirely new to the folks at Seeed. Seeed Fusion has been offering support in design for manufacturing for as long as we can remember. For instance, Seeed has provided design for manufacturing support for Hoofstep, a Horsetech company that develops horse wearable to monitor the well-being of horses and analyze their behavior using AI technology. Hoofstep has successfully launched their special headgear for horses on Kickstarter in February 2019, and is now helping horse owners all over Sweden to supervise and improve their horses’ lives.

Seeed’s design for manufacturing service has also helped to bring the Strawbees Quirkbot to life. Created by Kids Hack Day in the innovation hub of Stockholm, the Quirkbot is a microcontroller toy that can be used with readily available materials like drinking straws, LEDs, and hobby servo motors, to build and program funky robotic creatures into structures limited only by one’s imagination. With its “squeeze on electronics concept” and easy-to-use visual programming interface, the Quirkbot is designed to enable anyone regardless of age to build their own interactive project.

We don’t want to help only after your designs have run into manufacturing problems. We want you to be able to go straight into finding out whether your designs are optimized for production. Thus, we are making our design for manufacturing service official, by launching the Fusion DFX service as an addition to our family of Seeed Fusion services!

Here’s how the service works:

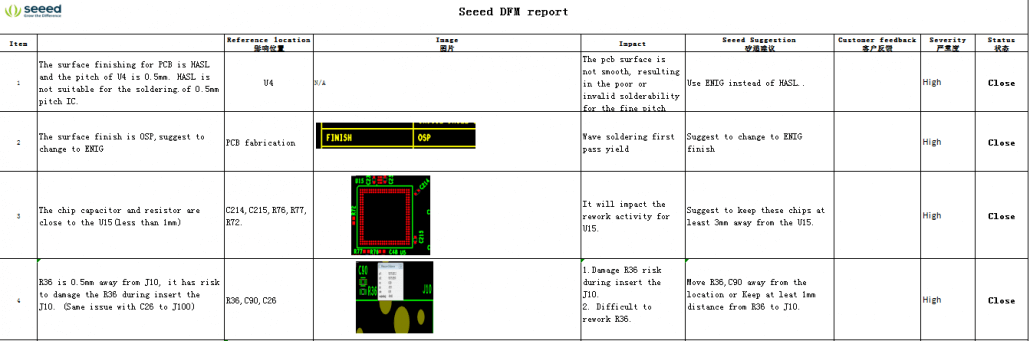

The DFX report covers various facets of PCB (and PCBA) design, such as PCB Design for Manufacturing (DFM), Testing (DFT), Assembly (DFA) and Cost (DFC), and hence its name “Design for X”. Shown below is an excerpt of the Seeed DFX report.

To find out how the Seeed Fusion DFX service can help you to achieve greater efficiency during product development, download the following file for more details on the services offered by the DFX reports.

Apply with 3 simple steps:

Step 1: Firstly, ensure that your project fulfills the following requirements:

- Projects should have a certain degree of complexity, with more than 30 different components on your PCB board.

- Projects should also be of electronics designs.

Step 2: Prepare an introduction of your project and include basic information such as the Gerber package, PCB fabrication instructions, the Bill of Materials (BOM), assembly drawing, schematic, test specification, package requirement and package drawing, the application area of your project, and any special requirements. Details on what to include for each segment is reflected in the file above.

Step 3: Send your application to us via email at [email protected]. The prices for each item in the service is shown in the table below.

|

Items |

Content |

Cost |

|

|

1. |

DFX Analysis |

DFM/DFT/DFA/DFC |

800 USD |

|

2. |

BOM Optimization |

1. Seeed provides alternative 2. Seeed help to check the component lifetime |

|

|

3. |

First Article Inspection |

Seeed will provide a detailed inspection record, trial report, test result summary during NPI |

300 USD |

|

4. |

Traceability |

A serial number printed on each board for MES system traceability |

0.2 USD/board |

|

5. |

Certification Handling Fee |

CE, FCC |

200 USD |

|

Telec |

100 USD |

||

|

CPSIA |

500 USD |

||

|

6. |

Reliability Testing Fee |

Thermal shock/cross-section/low & high temperature/shear test/vibration… |

300 USD |

Now you may sit back and relax, and our team will get back to you towards the end of the month to guide you on the further course of action to take.

Once designs are reviewed and tweaked based on DFX feedback, they will be ready to be fabricated by the Seeed Fusion PCB Assembly (PCBA) service. Seeed’s mission has always been to bridge the gap between makers and markets. Hence, to further close this gap, Seeed Fusion is offering to return the fees paid for the Seeed Fusion DFX service when you use the Seeed Fusion PCBA service to manufacture more than 500 PCBs.

With 10 years of experience in hardware manufacture, Seeed Fusion is no stranger to design for manufacturing. Utilizing the resources and expertise available here at Seeed, we hope to bulldoze the manufacturing obstacles that are hindering makers from bringing their product to the market through the new Seeed Fusion DFX Service. For further inquiries on the Seeed Design For X Service, contact us at [email protected].